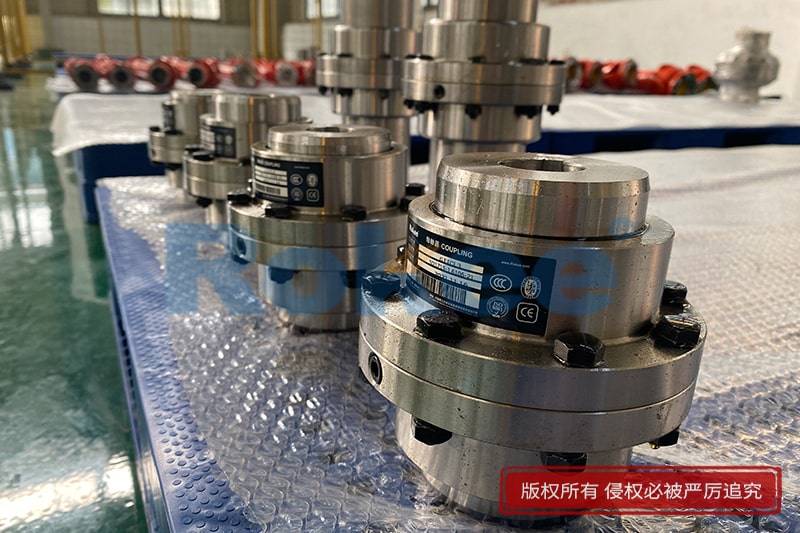

Crowned Tooth Shaft Coupling

Rokee® provide Crowned Tooth Shaft Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of power transmission systems, shaft couplings play a pivotal role in connecting two rotating shafts to transmit torque while accommodating various forms of misalignment. Among the diverse types of couplings available, crowned tooth shaft couplings stand out for their exceptional ability to handle angular, parallel, and axial misalignments simultaneously, making them a preferred choice in numerous industrial settings.

The fundamental purpose of any shaft coupling is to bridge the gap between two shafts that are not perfectly aligned, ensuring efficient torque transfer without causing excessive stress or wear on the connected components. Misalignments in rotating shafts can arise from a variety of factors, including manufacturing tolerances, installation errors, thermal expansion and contraction during operation, and structural deflection under load. Crowned tooth shaft couplings are specifically engineered to address these challenges, offering a robust and reliable solution for high-torque, high-speed applications where precision and durability are paramount.

Design Characteristics of Crowned Tooth Shaft Couplings

Crowned tooth shaft couplings, also known as crowned gear couplings, are a type of rigid-flexible coupling that consists of two main components: a pair of toothed hubs and an outer sleeve (or flange) with internal teeth. The defining feature of this coupling design is the crowned profile of the teeth on the hubs. Unlike straight-tooth couplings, where the tooth contact is limited to a narrow line, the crowned teeth have a convex curvature that allows for a larger contact area and greater flexibility in accommodating misalignments.

The basic structure of a crowned tooth shaft coupling typically includes two hubs, each with external crowned teeth, which mesh with the internal teeth of a common sleeve. The hubs are attached to the ends of the shafts using keys, splines, or shrink fits, ensuring a secure connection that can transmit high levels of torque. The sleeve, which encloses the meshing teeth, may be a single piece or split into two halves for easier installation and maintenance. Split sleeves are particularly advantageous in applications where the shafts cannot be easily moved apart during coupling replacement.

The tooth profile of crowned tooth couplings is carefully designed to optimize load distribution and minimize wear. The crown radius of the teeth is a critical design parameter; it determines the coupling’s ability to accommodate angular misalignment. A larger crown radius allows for greater angular misalignment but may reduce the contact area, while a smaller radius increases the contact area but limits misalignment capacity. Manufacturers tailor the crown radius to suit specific application requirements, balancing misalignment capability with torque-carrying capacity.

Another important design aspect is the material selection for the coupling components. Given the high loads and potential for wear, the hubs and sleeves are typically made from high-strength alloy steels, such as nickel-chromium steel or manganese steel, which offer excellent tensile strength, fatigue resistance, and wear resistance. The teeth may also undergo surface treatments, such as carburizing, quenching, and tempering, to enhance their hardness and durability. In some cases, non-metallic materials or composite coatings may be used for specialized applications where corrosion resistance or noise reduction is a priority.

Lubrication is a critical component of the design of crowned tooth shaft couplings. The meshing teeth operate under high contact pressures, and proper lubrication is essential to reduce friction, minimize wear, and dissipate heat. Most crowned tooth couplings are lubricated with grease or oil, and they are equipped with seals or gaskets to prevent lubricant leakage and protect the teeth from contamination by dust, dirt, or moisture. Some designs feature grease fittings or oil ports to facilitate regular lubrication without disassembling the coupling.

Working Principles of Crowned Tooth Shaft Couplings

The operation of a crowned tooth shaft coupling revolves around the interaction between the crowned teeth of the hubs and the internal teeth of the sleeve. When torque is applied to one shaft, it is transmitted through the hub to the meshing teeth, which then transfer the torque to the sleeve and ultimately to the second hub and shaft. The key to the coupling’s functionality lies in the crowned tooth profile, which allows for relative movement between the hubs and the sleeve to accommodate misalignments.

Angular misalignment occurs when the axes of the two shafts intersect at an angle. The crowned teeth of the hubs enable the teeth to mesh smoothly even when the shafts are not perfectly coaxial. As the shafts rotate, the convex surface of the crowned teeth slides against the internal teeth of the sleeve, distributing the load evenly across the tooth contact area. This sliding action is minimized by proper lubrication, which reduces friction and wear.

Parallel misalignment, also known as offset misalignment, occurs when the axes of the two shafts are parallel but not coincident. Crowned tooth couplings accommodate parallel misalignment through the radial movement of the hubs within the sleeve. The crowned tooth profile allows the teeth to maintain contact even when the hubs are offset, ensuring continuous torque transmission. The amount of parallel misalignment that a coupling can handle depends on the length of the teeth and the crown radius.

Axial misalignment, or end float, occurs when the shafts move along their axial direction. Crowned tooth couplings can accommodate axial misalignment due to the clearance between the teeth and the sleeve. The internal teeth of the sleeve are longer than the external teeth of the hubs, providing sufficient space for the hubs to move axially without losing mesh. This axial flexibility is particularly important in applications where thermal expansion and contraction of the shafts cause axial movement during operation.

In addition to accommodating misalignments, crowned tooth shaft couplings also help to dampen vibrations and absorb shock loads. The meshing teeth, combined with the lubrication, act as a buffer, reducing the transmission of vibrations from one shaft to the other. This vibration damping capability helps to protect the connected equipment, such as motors, pumps, and gearboxes, from premature wear and failure.

Key Advantages of Crowned Tooth Shaft Couplings

Crowned tooth shaft couplings offer a range of advantages that make them well-suited for demanding industrial applications. One of their primary advantages is their high torque-carrying capacity. The large contact area between the crowned teeth and the internal sleeve teeth allows them to transmit significantly higher torques compared to other types of flexible couplings, such as jaw couplings or elastomeric couplings. This makes them ideal for heavy-duty applications, such as large industrial motors, compressors, and turbines.

Another major advantage is their ability to accommodate multiple types of misalignments simultaneously. Unlike some couplings that can only handle one type of misalignment, crowned tooth couplings can handle angular, parallel, and axial misalignments at the same time, providing greater flexibility in system design and installation. This reduces the need for precise alignment during installation, saving time and labor costs.

Crowned tooth shaft couplings also exhibit excellent durability and long service life. The use of high-strength materials and surface treatments, combined with proper lubrication, ensures that the coupling can withstand harsh operating conditions, including high speeds, high temperatures, and heavy loads. The even load distribution across the teeth minimizes wear, reducing the frequency of maintenance and replacement.

In addition, these couplings operate with low noise and vibration. The smooth meshing of the crowned teeth, coupled with effective lubrication, results in quiet operation, making them suitable for applications where noise levels are a concern, such as in residential areas or precision manufacturing facilities. The vibration damping capability also helps to improve the overall stability and performance of the power transmission system.

Crowned tooth shaft couplings are also highly versatile. They can be customized to suit a wide range of application requirements, including different shaft sizes, torque ratings, and misalignment capacities. Split sleeve designs offer easy installation and maintenance, allowing for coupling replacement without disassembling the entire power transmission system. This versatility makes them a popular choice across various industries.

Typical Applications of Crowned Tooth Shaft Couplings

Due to their high torque capacity, flexibility, and durability, crowned tooth shaft couplings are used in a wide range of industrial applications. One of the most common applications is in the power generation industry, where they are used to connect turbines to generators. In power plants, the shafts of turbines and generators are often subject to misalignments due to thermal expansion and contraction, and crowned tooth couplings provide a reliable solution for transmitting the high torques generated by the turbines to the generators.

Another major application area is the heavy machinery industry, including mining, construction, and agriculture. Equipment such as excavators, bulldozers, and tractors require couplings that can handle high torques and accommodate misalignments caused by the uneven terrain and heavy loads. Crowned tooth couplings are used in the drive systems of these machines, connecting engines to gearboxes and other components.

The oil and gas industry also relies heavily on crowned tooth shaft couplings. In oil refineries and natural gas processing plants, pumps, compressors, and other rotating equipment operate under harsh conditions, including high pressures, high temperatures, and corrosive environments. Crowned tooth couplings are used to connect these machines, ensuring efficient torque transmission and reliable operation even in these challenging conditions.

In the manufacturing industry, crowned tooth shaft couplings are used in a variety of equipment, such as conveyor systems, printing presses, and machine tools. Conveyor systems, which are used to transport materials in factories and warehouses, require couplings that can handle the continuous torque and accommodate misalignments caused by the long length of the conveyor shafts. Printing presses and machine tools, on the other hand, require precise torque transmission and low vibration to ensure product quality, making crowned tooth couplings an ideal choice.

Marine applications also benefit from the use of crowned tooth shaft couplings. Ships and other marine vessels have complex power transmission systems that connect engines to propellers. The shafts in these systems are subject to misalignments due to the movement of the vessel and thermal expansion, and crowned tooth couplings provide a robust solution for transmitting high torques in marine environments.

Maintenance Considerations for Crowned Tooth Shaft Couplings

To ensure the optimal performance and long service life of crowned tooth shaft couplings, proper maintenance is essential. One of the most important maintenance tasks is regular lubrication. The meshing teeth of the coupling operate under high contact pressures, and insufficient lubrication can lead to increased friction, wear, and overheating. It is important to use the correct type of lubricant, as specified by the manufacturer, and to lubricate the coupling at regular intervals. The frequency of lubrication depends on the operating conditions, such as speed, load, and temperature.

Regular inspection of the coupling components is also crucial. During inspections, check for signs of wear, such as tooth damage, pitting, or corrosion. Excessive wear on the teeth can reduce the coupling’s torque-carrying capacity and misalignment capability, leading to premature failure. Inspect the seals and gaskets for leaks, as lubricant leakage can lead to insufficient lubrication and contamination of the teeth. Also, check the tightness of the fasteners, such as bolts and nuts, to ensure that the hubs are securely attached to the shafts.

Alignment checks should be performed periodically, especially after maintenance or when the equipment is moved. While crowned tooth couplings can accommodate misalignments, excessive misalignment can lead to increased wear and reduced service life. Use precision alignment tools, such as laser alignment systems, to ensure that the shafts are aligned within the coupling’s specified limits. If misalignment is detected, adjust the position of the connected equipment to correct it.

In the event of component damage, such as tooth wear or seal failure, it is important to replace the damaged parts promptly. Using damaged components can lead to further damage to the coupling and the connected equipment. When replacing parts, use genuine replacement parts from the manufacturer to ensure compatibility and performance. Split sleeve couplings make replacement easier, as the sleeve can be removed without moving the shafts.

Proper storage of crowned tooth shaft couplings is also important to prevent damage before installation. Store the couplings in a clean, dry environment, away from moisture, dust, and corrosive substances. Avoid stacking heavy objects on the couplings, as this can cause deformation of the teeth or other components. If the coupling is disassembled for storage, apply a light coat of lubricant to the teeth to prevent rust.

Conclusion

Crowned tooth shaft couplings are a vital component in modern power transmission systems, offering a unique combination of high torque-carrying capacity, flexibility in accommodating misalignments, and durability. Their design, which features crowned teeth and a meshing sleeve, enables them to transmit torque efficiently while handling angular, parallel, and axial misalignments simultaneously. This makes them suitable for a wide range of industrial applications, from power generation and heavy machinery to oil and gas processing and marine systems.

The key advantages of crowned tooth shaft couplings, including their high torque capacity, versatility, low noise and vibration, and long service life, make them a preferred choice over other types of couplings in many demanding applications. Proper maintenance, including regular lubrication, inspection, and alignment checks, is essential to ensure their optimal performance and extend their service life.

As industrial systems continue to evolve, with increasing demands for higher efficiency, reliability, and performance, crowned tooth shaft couplings are likely to remain a critical component in power transmission systems. Their ability to adapt to various operating conditions and accommodate the challenges of misalignment and high torque makes them an indispensable part of modern mechanical engineering.

« Crowned Tooth Shaft Coupling » Post Date: 2023/9/21

URL: https://www.rokeecoupling.com/en/customer-cases/crowned-tooth-shaft-coupling.html

- Structural Drawing Of Large Fan Diaphragm Coupling

- Working Principle Of Hydraulic Gear Coupling

- Flexible Pump Coupling Assembly Drawing

- Flexible Plum Couplings Opening Keyway

- Torque of Bush Pin Coupling

- Small Diaphragm Couplings

- Catalogue of Shim Pack Couplings

- Gear Pin Coupling Drawing

- Cross Axle Universal Coupling Design

- Purpose Of Jaw Coupling