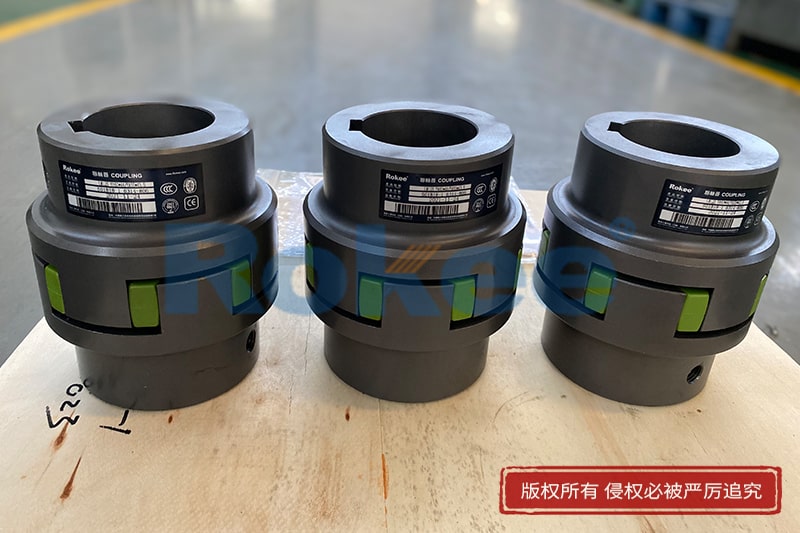

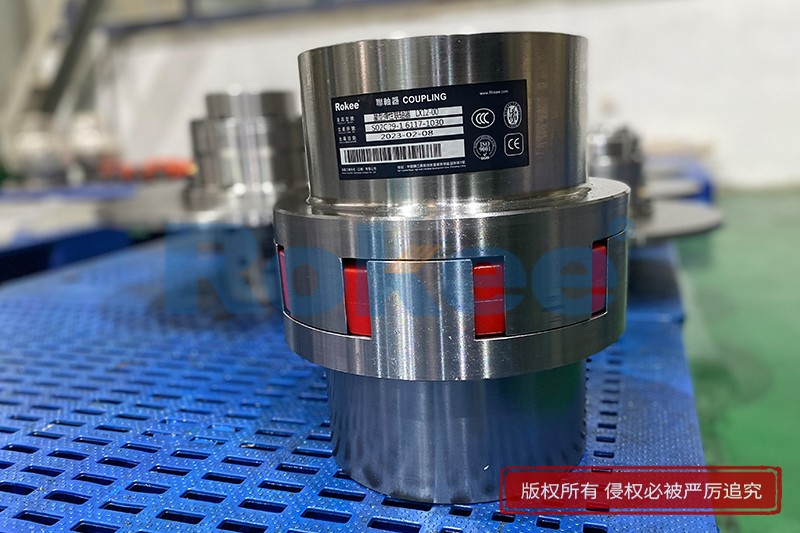

Jaw Flexible Coupling

Rokee® is a Jaw Flexible Coupling Supplier from China, customized jaw flexible coupling according to the drawings which provided by the customer, selling chinese national standard jaw flexible coupling, support export, due to excellent quality, complete technical services and superior cost performance, Rokee® industrial coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Flexible Couplings are one of the major types of couplings. They find use to connect two shafts, end-to-end in the same line to transmit power that is torque from one shaft to another, thereby causing both to rotate in unison, at the same rpm.

The purpose of a Elastic Coupling is to transmit torque from one piece of rotating equipment to another, while accepting at the same time a small amount of misalignment. Flexible coupling misalignment is expressed, as an order of magnitude, in thousandths of an inch. Actual misalignment, expressed in coupling terms, is angular in nature and expressed in angular units, that is, degrees. How much misalignment is a function of the coupling type and installation. An installation variable is the equipment movement due to the temperature changes taking place in the machines as they go from the non-operating state to operation. Some angular values will be used in the discussion of the various types, but, again, these are for reference only. Each application must be reviewed using the type of coupling selected and the specific design proposed by the vendor.

The plum coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, it has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

Flexible plum blossom coupling is made up of semi-shaft coupling with the same protruding claw and flexible component.utilizing the plum blossom elastic component put between the protruding claw and two half shaft coupling.in order to realize the connection of two semiaxis devices.

Jaw coupling has compensating by two axle to be relative skew,reducing shaking buffering.smaller diameter simple structure.without lubricating.bearing large capacity,and convenient repair But the semi-shaft coupling needs to move along the axial while changing the elastic component.

Claw coupling is suitable for two with axis,start frequent,positive and negative change,low-speed and medium speed.medium and small powerrotate axle department,requiring working dependability high working position;it is not suitable for the heavily loaded and restricted axial in size.Two axis put in the difficult position after exchange of flexible component.

LMPK Plum-shaped Flexible Coupling

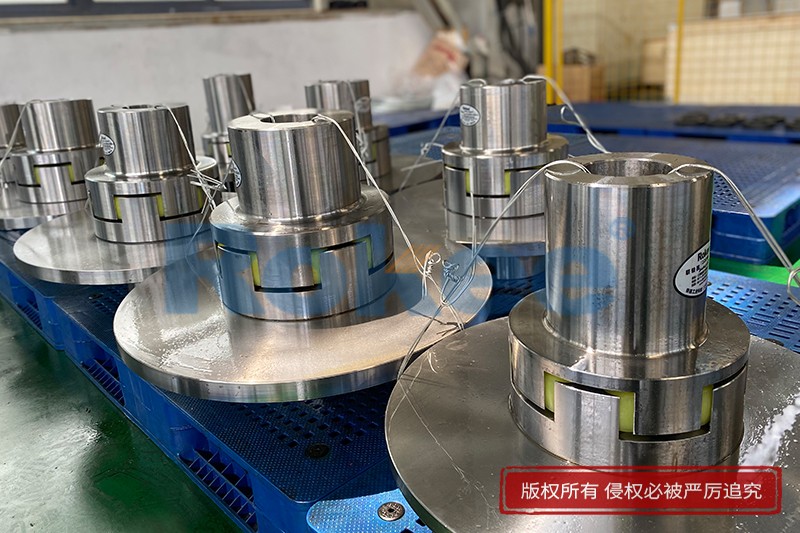

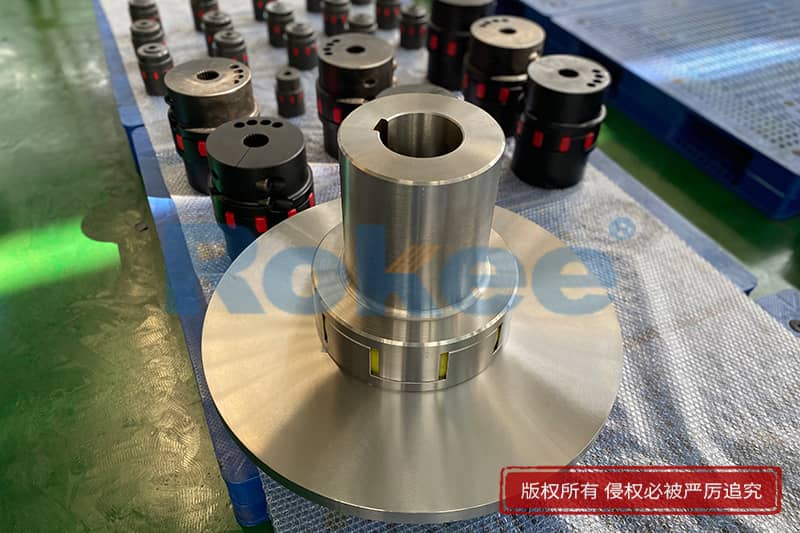

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.LMZ-II Plum-shaped Flexible Coupling

LMZ-II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.LMZ-I Plum-shaped Flexible Coupling

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.LMS Plum-shaped Flexible Coupling

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.LMD Plum-shaped Flexible Coupling

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.LM Plum-shaped Flexible Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating various forms of misalignment. Among the diverse types of couplings available, jaw flexible couplings have emerged as a popular choice across numerous industrial sectors due to their simplicity, reliability, and cost-effectiveness.

Structural Composition of Jaw Flexible Couplings

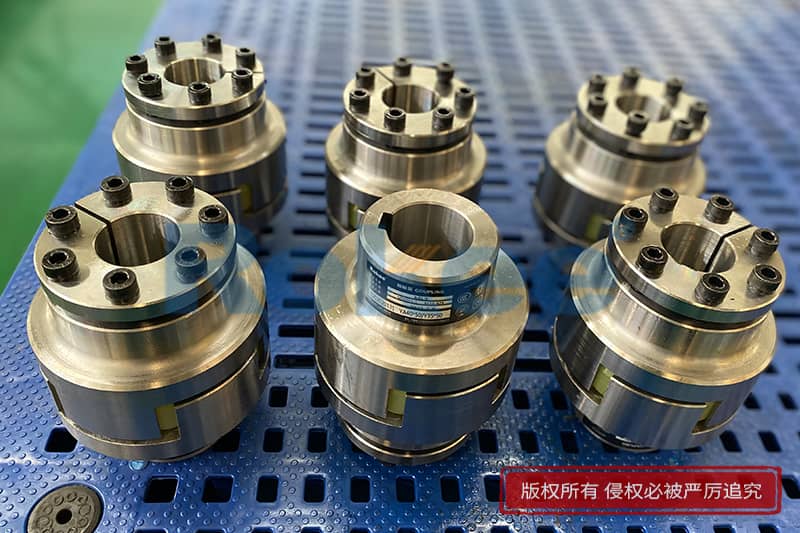

Jaw flexible couplings are characterized by a relatively straightforward yet robust design, consisting of three primary components: two jaw-shaped hubs and an elastomeric element (often referred to as a spider or insert) positioned between them. Each hub features a series of evenly spaced, radially extending jaws that interlock with the corresponding projections on the elastomeric insert. The hubs are typically designed to mount onto the shafts of the driving and driven machinery, with common mounting methods including keyway connections, set screws, or compression fittings to ensure a secure torque transfer.

The elastomeric insert, which is the core flexible component of the coupling, is engineered to fit precisely between the two hubs. Its geometry is tailored to match the jaw profile of the hubs, creating a positive engagement that prevents slippage during operation. The insert may also incorporate grooves or notches to enhance flexibility and distribute stress evenly, thereby extending its service life. Depending on the application requirements, the insert can be manufactured in various shapes, such as cylindrical, hexagonal, or with curved jaws, to optimize performance under different torque and misalignment conditions.

Working Principles of Jaw Flexible Couplings

The primary function of a jaw flexible coupling is to transmit rotational torque from the driving shaft to the driven shaft while compensating for three main types of shaft misalignment: angular misalignment (where the shafts are not collinear but intersect at a point), parallel misalignment (where the shafts are parallel but offset from each other), and axial misalignment (where the shafts move along their axial direction). The elastomeric insert plays a pivotal role in achieving this functionality.

When torque is applied to the driving hub, the jaws of the hub exert a force on the elastomeric insert. The insert, being flexible, deforms slightly to transfer this torque to the driven hub, which then rotates in synchronization with the driving hub. During this process, any misalignment between the two shafts causes the insert to undergo additional elastic deformation. For angular misalignment, the insert bends at an angle to accommodate the difference in shaft orientation; for parallel misalignment, it stretches or compresses laterally to bridge the offset between the shafts; and for axial misalignment, it expands or contracts along the axial direction to absorb the relative movement of the shafts. Once the misalignment is corrected or the torque is removed, the elastomeric insert reverts to its original shape, thanks to its elastic properties.

Another important working principle of jaw flexible couplings is their ability to dampen vibration and reduce noise. The elastomeric material of the insert acts as a shock absorber, absorbing the vibrational energy generated by the rotating shafts and preventing it from being transmitted to other parts of the machinery. This vibration damping effect not only improves the comfort of the working environment but also reduces wear and tear on other mechanical components, thereby enhancing the overall reliability and lifespan of the system.

Key Advantages of Jaw Flexible Couplings

Jaw flexible couplings offer a multitude of advantages that make them suitable for a wide range of applications. One of the most significant advantages is their simplicity in design and installation. Unlike complex couplings that require specialized tools or skilled technicians for assembly, jaw flexible couplings can be easily installed and removed with basic tools, reducing downtime during maintenance or replacement.

Another major advantage is their excellent misalignment compensation capability. As mentioned earlier, these couplings can effectively accommodate angular, parallel, and axial misalignments, which are common in many mechanical systems due to factors such as manufacturing tolerances, thermal expansion, and structural deflection. This ability to compensate for misalignment reduces the stress on shafts, bearings, and other components, minimizing the risk of premature failure.

Vibration damping and noise reduction are additional key benefits of jaw flexible couplings. The elastomeric insert absorbs vibrational shocks and reduces the transmission of noise, making them ideal for applications where quiet operation is desired, such as in precision machinery, medical equipment, and consumer appliances.

Jaw flexible couplings also exhibit good torque transmission capacity relative to their size and weight. They can handle a wide range of torque values, from low to moderate, making them suitable for both light-duty and medium-duty applications. Additionally, the elastomeric insert provides a certain degree of overload protection. In the event of a sudden torque spike, the insert may deform or shear, preventing damage to the driving and driven machinery. This sacrificial nature of the insert makes it a cost-effective component to replace compared to repairing or replacing expensive shafts or gearboxes.

Cost-effectiveness is another notable advantage of jaw flexible couplings. Their simple design results in lower manufacturing costs compared to more complex couplings, such as gear couplings or disc couplings. Furthermore, their low maintenance requirements and long service life contribute to reduced overall operational costs over time.

Material Selection for Jaw Flexible Couplings

The performance and durability of jaw flexible couplings are heavily dependent on the materials used for their components. The selection of materials is typically based on the application requirements, including torque capacity, operating temperature, environmental conditions, and chemical exposure.

For the hubs, common materials include various types of metals such as aluminum alloy, cast iron, and steel. Aluminum alloy is preferred for light-duty applications due to its lightweight, corrosion resistance, and good machinability. It is commonly used in applications such as small electric motors, pumps, and fans. Cast iron is suitable for medium-duty applications where higher torque capacity and rigidity are required. It is widely used in industrial machinery, such as compressors, conveyors, and agricultural equipment. Steel, particularly alloy steel, is used for heavy-duty applications that require high torque transmission and resistance to wear and impact. It is often employed in mining machinery, construction equipment, and marine propulsion systems.

The elastomeric insert is typically made from materials such as natural rubber, nitrile rubber (NBR), neoprene (CR), polyurethane (PU), and silicone rubber. Each material has its own unique properties that make it suitable for specific applications. Natural rubber offers excellent elasticity and vibration damping capabilities but has limited resistance to oil, ozone, and high temperatures. It is suitable for general-purpose applications in clean, dry environments. Nitrile rubber is highly resistant to oil, fuel, and grease, making it ideal for applications where the coupling may come into contact with these substances, such as in automotive engines, hydraulic systems, and fuel pumps. Neoprene rubber exhibits good resistance to ozone, weathering, and chemicals, making it suitable for outdoor applications or environments with exposure to harsh chemicals. Polyurethane offers high tensile strength, abrasion resistance, and good load-bearing capacity. It also has a wider temperature range compared to natural rubber and is resistant to oil and chemicals. Silicone rubber is capable of withstanding extreme temperatures, ranging from -50°C to 200°C, and has excellent resistance to ozone and weathering. It is commonly used in high-temperature applications such as industrial ovens, steam turbines, and aerospace equipment.

Typical Applications of Jaw Flexible Couplings

Due to their versatile properties, jaw flexible couplings find applications in a wide range of industries and mechanical systems. One of the most common applications is in the automotive industry, where they are used to connect the engine to the transmission, as well as in various auxiliary systems such as water pumps, alternators, and air conditioning compressors. The vibration damping and misalignment compensation capabilities of these couplings help to improve the smoothness of operation and reduce wear on automotive components.

In the industrial machinery sector, jaw flexible couplings are widely used in pumps, compressors, fans, blowers, conveyors, and mixers. For example, in centrifugal pumps, the coupling connects the motor shaft to the pump impeller shaft, accommodating any misalignment that may occur due to thermal expansion or installation errors. In conveyors, they transmit torque from the motor to the conveyor belt drive, ensuring reliable operation even in harsh industrial environments.

Precision machinery and equipment, such as machine tools, robotics, and medical devices, also benefit from the use of jaw flexible couplings. The low vibration and high precision of these couplings help to maintain the accuracy of machining operations in machine tools and ensure the smooth movement of robotic arms. In medical equipment, such as diagnostic scanners and surgical tools, the quiet operation and reliability of jaw flexible couplings are essential for patient safety and comfort.

The agricultural industry uses jaw flexible couplings in various equipment such as tractors, harvesters, and irrigation pumps. These couplings are able to withstand the harsh environmental conditions encountered in agriculture, such as dust, dirt, and moisture, while providing reliable torque transmission.

Other applications of jaw flexible couplings include renewable energy systems (such as wind turbines and solar pumps), marine equipment, and household appliances (such as washing machines and refrigerators). In each of these applications, the coupling's ability to accommodate misalignment, dampen vibration, and transmit torque efficiently makes it an indispensable component.

Maintenance and Troubleshooting of Jaw Flexible Couplings

Proper maintenance is essential to ensure the optimal performance and long service life of jaw flexible couplings. Regular maintenance practices include visual inspections, lubrication (if required), and periodic replacement of the elastomeric insert.

Visual inspections should be conducted regularly to check for signs of wear, damage, or misalignment. During inspection, attention should be paid to the condition of the elastomeric insert, looking for cracks, tears, hardening, or excessive wear. The hubs should also be inspected for signs of corrosion, deformation, or damage to the jaws. Additionally, the coupling should be checked for proper alignment using tools such as a straightedge, feeler gauge, or laser alignment tool. Misalignment beyond the coupling's rated capacity can lead to increased stress on the insert and other components, resulting in premature failure.

Lubrication is generally not required for jaw flexible couplings with elastomeric inserts, as the insert itself acts as a self-lubricating component. However, if the coupling uses metallic components that require lubrication (such as set screws or keyways), it is important to apply the appropriate lubricant at regular intervals to prevent corrosion and ensure smooth operation.

The elastomeric insert is the most wear-prone component of the jaw flexible coupling and should be replaced periodically, even if no visible signs of damage are present. The replacement interval depends on the application conditions, such as operating temperature, torque load, and the frequency of misalignment. It is recommended to follow the manufacturer's guidelines for replacement intervals to avoid unexpected failures.

Common troubleshooting issues with jaw flexible couplings include excessive vibration, noise, and premature failure of the insert. Excessive vibration may be caused by misalignment, a worn or damaged insert, or imbalance in the shafts. To resolve this issue, the coupling should be realigned, and the insert should be inspected and replaced if necessary. Excessive noise can be a result of metal-to-metal contact between the hubs, which may occur if the insert is severely worn or missing. In this case, the insert should be replaced immediately to prevent further damage to the hubs. Premature failure of the insert may be caused by operating beyond the coupling's torque capacity, exposure to extreme temperatures or chemicals, or improper installation. To address this, the coupling should be sized correctly for the application, the appropriate insert material should be selected, and proper installation procedures should be followed.

Conclusion

Jaw flexible couplings have established themselves as a versatile and reliable solution for power transmission in a wide range of mechanical systems. Their simple design, excellent misalignment compensation, vibration damping capabilities, and cost-effectiveness make them a preferred choice for both light-duty and medium-duty applications across various industries. The selection of appropriate materials for the hubs and elastomeric insert is crucial to ensuring optimal performance in specific operating conditions. Regular maintenance, including visual inspections and periodic replacement of the insert, is essential to maximize the service life of the coupling and prevent unexpected failures.

As technology continues to advance, jaw flexible couplings are likely to undergo further improvements in material technology and design, enhancing their performance and expanding their range of applications. Whether in automotive, industrial, precision machinery, or agricultural applications, jaw flexible couplings will remain an integral component of mechanical power transmission systems, contributing to the efficiency, reliability, and safety of modern machinery.

« Jaw Flexible Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/blog/jaw-flexible-coupling.html

Tags: pu sandwich panel line

- 2024-07-01High Quality Jaw Flexible Couplings

- 2024-07-01Installation of Jaw Flexible Coupling

- 2024-07-01Jaw Flexible Coupling Advantages

- 2024-07-01Jaw Flexible Coupling Assembly Drawing

- 2024-07-01Jaw Flexible Coupling Calculation

- 2024-07-01Jaw Flexible Coupling Design

- 2024-07-01Jaw Flexible Coupling Pictures

- 2024-07-01Jaw Flexible Coupling Price

- 2024-07-01Jaw Flexible Coupling Sales

- 2024-07-01Jaw Flexible Coupling Standard Sizes

- 2024-07-01Jaw Flexible Couplings Factory

- 2024-07-01Jaw Flexible Couplings For Sale

- 2024-07-01Lubrication of Jaw Flexible Coupling

- 2024-07-01Machine Drawing of Jaw Flexible Couplings

- 2024-07-01Maintenance of Jaw Flexible Coupling

- 2024-07-01Misalignment Tolerance of Jaw Flexible Coupling

- 2024-06-18Gap Chart of Jaw Flexible Couplings

- 2024-06-18Function of Jaw Flexible Couplings

- 2024-06-18Exploded View of Jaw Flexible Couplings

- 2024-06-18Disadvantages of Jaw Flexible Coupling

- 2024-06-18Customized Jaw Flexible Couplings

- 2024-06-18Components of Jaw Flexible Coupling

- 2024-06-18Coaxiality of Jaw Flexible Coupling

- 2024-06-18Application of Jaw Flexible Couplings

- 2024-06-18Angle of Jaw Flexible Coupling

- 2024-06-18Alignment of Jaw Flexible Coupling

- 2024-06-12Parts of Jaw Flexible Coupling

- 2024-06-12Procurement of Jaw Flexible Coupling

- 2024-06-12Size Calculation of Jaw Flexible Coupling

- 2024-06-12Size Chart of Jaw Flexible Couplings

- 2024-06-12Specifications of Jaw Flexible Coupling

- 2024-06-12Stiffness of Jaw Flexible Coupling

- 2024-06-12Tagging of Jaw Flexible Coupling

- 2024-06-12Torque of Jaw Flexible Coupling

- 2024-06-12Types of Jaw Flexible Coupling

- 2024-06-07Grease of Jaw Flexible Coupling

- 2024-06-07Structural Diagram of Jaw Flexible Couplings

- 2024-06-07Jaw Flexible Couplings Manufacturer

- 2024-06-07Purpose of Jaw Flexible Couplings

- 2024-06-07Uses of Jaw Flexible Couplings

- 2024-06-07Jaw Flexible Couplings Wholesale

- 2024-06-07Jaw Flexible Couplings Drawing

- 2024-06-07Jaw Flexible Coupling Manufacturing

- 2024-06-07Classification of Jaw Flexible Couplings

- 2024-06-07Engineering Drawing of Jaw Flexible Couplings

- 2024-06-04Working Principle of Jaw Flexible Coupling

- 2024-06-04Material of Jaw Flexible Coupling

- 2024-06-043D Model of Jaw Flexible Couplings

- 2024-06-04Catalogue of Jaw Flexible Couplings

- 2024-06-04Efficiency of Jaw Flexible Coupling

- 2024-06-04Jaw Flexible Coupling Brands

- 2024-06-04Jaw Flexible Couplings Company

- 2024-06-04Supply of Jaw Flexible Couplings

- 2024-06-04Schematic Diagram of Jaw Flexible Couplings

- 2024-06-04Jaw Flexible Coupling Models

- 2024-06-04High Performance Jaw Flexible Couplings

- 2024-06-04Jaw Flexible Couplings Supplier